Big Data and TLC allow to realize forecast model for energy production and improve the efficiency of a single windmill blade

The energy sector is undergoing a real technological revolution, as shown especially by the widespread of renewable sources such as wind and solar photovoltaic power.

One of the obstacles that hinders the further promotion of these technologies is the uncertain plant performance and, therefore, the difficulty of planning the necessary considerable investments. But as regards renewables it’s often hard to get hold of certain data on the available energy and the efficiency of conversion technologies, even it were sure that the right plant (in terms of technology and size) is located in the right place. However, nowadays ICT technologies can really help.

For instance, in order to know where to place a wind farm, data on the average availability of winds in the long term (years) and at different heights above the ground are necessary. The US Department of Energy published a website reporting wind data from all over the States, at a height of 30, 50 and 80 metres above the ground. A greatly detailed tool, essential for companies that are planning to invest in this field, and also for local governments and financers.

But more can be done. In fact, thanks to technological innovation, systems can be achieved for the exact and timely prediction of wind in extremely reduced surfaces. This type of research is conducted by all major electricity companies that own wind farms, such as Enel Green Power, which is a leader in this sector.

This is an important accomplishment in the energy field: up to now, after a site was chosen, the settings of plant’s turbines were based on wind data regarding the whole site. But a plant consists of dozens of machines (even hundreds) placed in several square metres: so that even if a strong effort is made, the optimisation of energy generation will never be fully achieved.

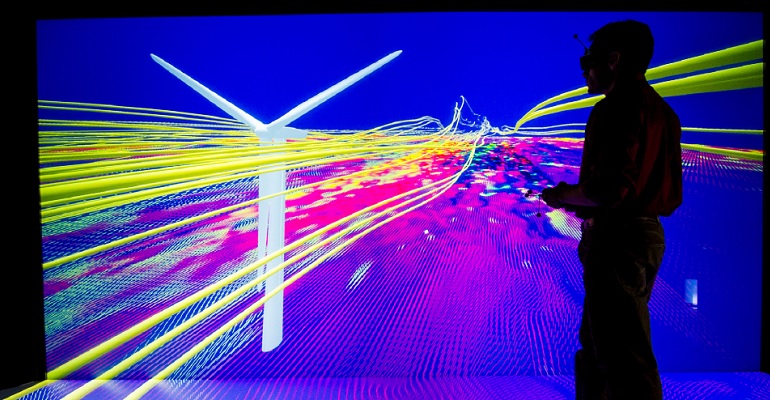

Instead, by using new powerful calculus software based on data collected by several sensors placed on each turbine and continuously sent (by Umts or other Tlc packages) to the control centre, it will soon be possible to adjust the blades of each turbine to the conditions of the wind.

In fact, already now exact forecasts can be made on the plant’s productibility in the very short term, which is a key data both to optimise the integration of the generated energy into the electricity grid and to enhance its value on the power stock exchange.